Innovative Solutions and Operational Excellence

Air Products continually innovates burner technologies with a variety of features to meet the varying needs of ferrous and non-ferrous metal producers.

- Flame shapes

- Heat release profiles

- Air-oxy-fuel options

- High and low momentum configurations

- Roof/sidewall/door mounting arrangements

- Water-cooled and non-water-cooled construction

- Low NOx capabilities

By matching the characteristics of the flame to the needs of each operation, Air Products' technology delivers maximum benefit with the most efficient use of oxygen and fuels, such as natural gas.

In addition, we use optimization algorithms to standardize production cycles and improve repeatability. Air Products offerings featuring Process Intelligence, use sensor and communications technology to monitor and control our gases and equipment, as well as track key process parameters. Your personnel can remotely access this data for improved process understanding.

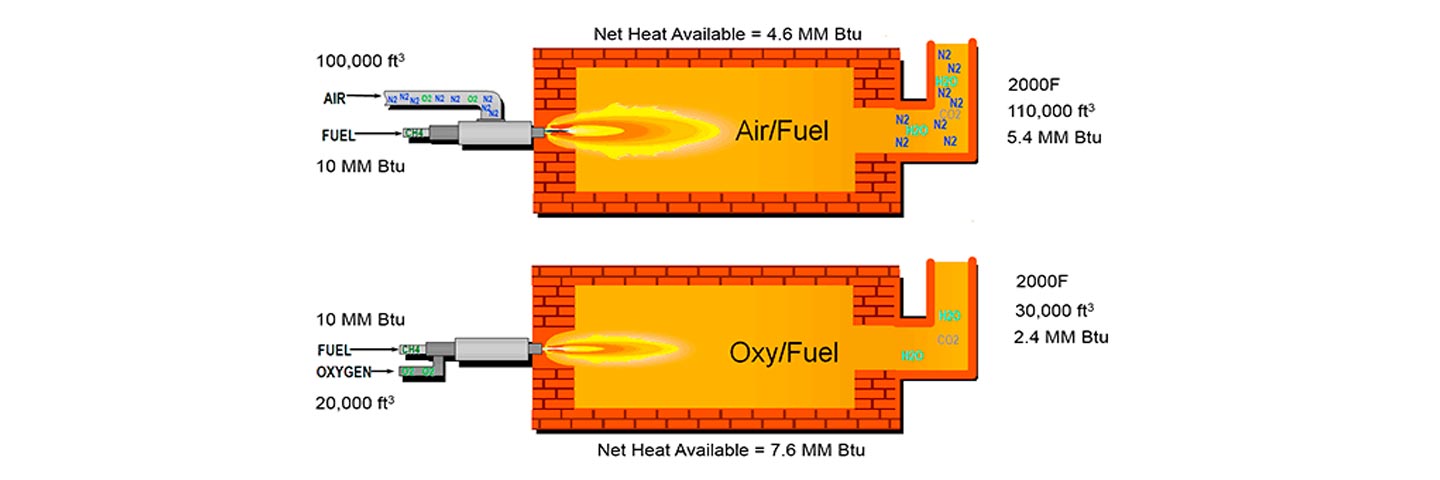

Available Heat Comparison: Air-fuel vs. Oxy-fuel Combustion

ADVANCED CLEAN ENERGY LABORATORY—VIRTUAL DEMONSTRATIONS TO GLOBAL LOCATIONS

Advanced Clean Energy Laboratory—Virtual Demonstrations to Global Locations

Count on Air Products' expertise…

Our industry experts can help you find the optimal solution to your operational challenges and suggest ways to boost your production.